Stucco Construction Details Builder Academy

Stucco Flashing Details Sidebar: By Ron Webber Login or Register to download the PDF version of this article. (332.98 kB) There are three stucco wall systems in use today: traditional three-coat stucco, so-called one-coat or synthetic stucco systems, and EIFS (Exterior Insulating Finish Systems).

Pin on House

Stucco Horizontal Expansion Joint. Stucco Termination at Cantilevered Wall. Stucco Casing Bead at Concrete Foundation. Stucco Outside Corner. Stucco Inside Corner (Typical) Stucco Inside Corner (Alternate) Stucco Corner Trim. Wood Corner Trim Over Stucco. Stucco Window Head.

Why Weep Screed and Deck to Wall Metal Are Necessary Parts of a

Stucco recipes. Three-coat stucco installation details. Metal lath based stucco wall installation. Thin coat stucco wall systems & installation. EIFS and synthetic stucco wall systems, success, issues, inspection, and problem diagnosis.

Stucco Construction Details Builder Academy

A new guide available for flashing and u0003waterproofing stucco buildings, this practical u0003reference focuses on different styles of top of wall caps on frame buildings; intended for designers and builders. It includes other guidance for general stucco work. Includes 242 pages and 125+ line drawingsu0003for comparing and selecting stucco.

Stucco Construction Details Builder Academy

Typical Kick-out Flashing 18. Typical Termination at Deck 19. Typical Coping 20. Typical Corner Bead 21. Typical Downspout Application 22. Typical Pipe Penetration 23. Typical Light Fixture 24. Typical Dryer Vent Finestone Stucco Wall System Typical Details Table of Contents (THIS PAGE INTENTIONALLY LEFT BLANK) This detail represents Master.

Window Flashing Details Stucco

1. Cap Flashing 3.01 2. Soffit / Fascia 1.0 3. Plate Line Flashing 4. Deck Flashing 4.0 5. Saddle Flashing 3.02 6. Inside Corner 1.0 7. Outside Corner 2.0 8. Window Head Flashing 1.0 9. Non-Flanged Window - Jamb 2.01 10. Non-Flanged Window - Head 2.02 11. Non-Flanged Window - Sill 2.03

EIFS/Stucco Inspections Tallahassee Real Estate Inspections

Set the window. Set the window in the opening, bedding the flanges in sealant. Tape the flanges. Put another layer of tape over the top and side flanges of the installed window. Install head flashing. If the job calls for it, install head flashing at the top of the window. The edges of walls also need attention.

Pin by Marteyn on Langkawi Home Marteyn & Marina Parapet, Roof

Typically made of aluminium or galvanized steel, flashing is any material used over joints in your walls or roof to prevent water from seeping through. You'll often find it around chimneys, vents or windows. Flashing is fairly easy to install.

Leakproof Window Flashing HowTo BuildingAdvisor

Step 1: Installing the Roofing Felt For step flashing with a stucco wall, you will be working in part on the roof. After you have gathered all your materials, you will lay roofing felt over the area that will have flashing. It is important to overlap any old roofing felt by at least one foot. Use your hammer and nails to secure the felt into place.

Pin on Building science

Flashings also integrate windows, doors and other building enclosure openings to drain to the exterior or water resistant barrier. The focus of this website is the details for design and construction necessary to prevent water intrusion of exterior building walls. These areas are addressed in publications for stucco buildings; windows and doors.

Drainage for Stucco JLC Online Stucco, Moisture Barriers

We Supply Roof Sealant Paints, Coatings and Sealers In a Range Of Colours. All Items Come With Free Delivery. Bulk Discounts Are Available On Request.

DETAILS Stucco walls, Stucco finishes, Stucco

The 3 options are: a) A generic weatherseal tape with adhesive to keep in place; b) Polyurethane sealant ASTM C-920, Type S, Grade NS, Class 25; ASTM C-719; c) Mortar fi ller into voids and between stones. D Support Angle. A galvanized metal bracket or clip capable of supporting 5 lb./LF of weight.

a diagram showing the structure of a brick wall and how it's attached

Product Manual — Best Practices for Flashing Details, Owens-Corning, Cultured Stone Brochure 10001459, October 2006,. Standard (excerpt) — Appendix X2 Stucco Details, ASTM E2266-11 Standard Guide for the Design and Construction of Low-Rise Frame Building Wall Systems to Resist Water Intrusion, ASTM, 2011;

Stucco Flashing Colorado's Construction Experts General Contractors

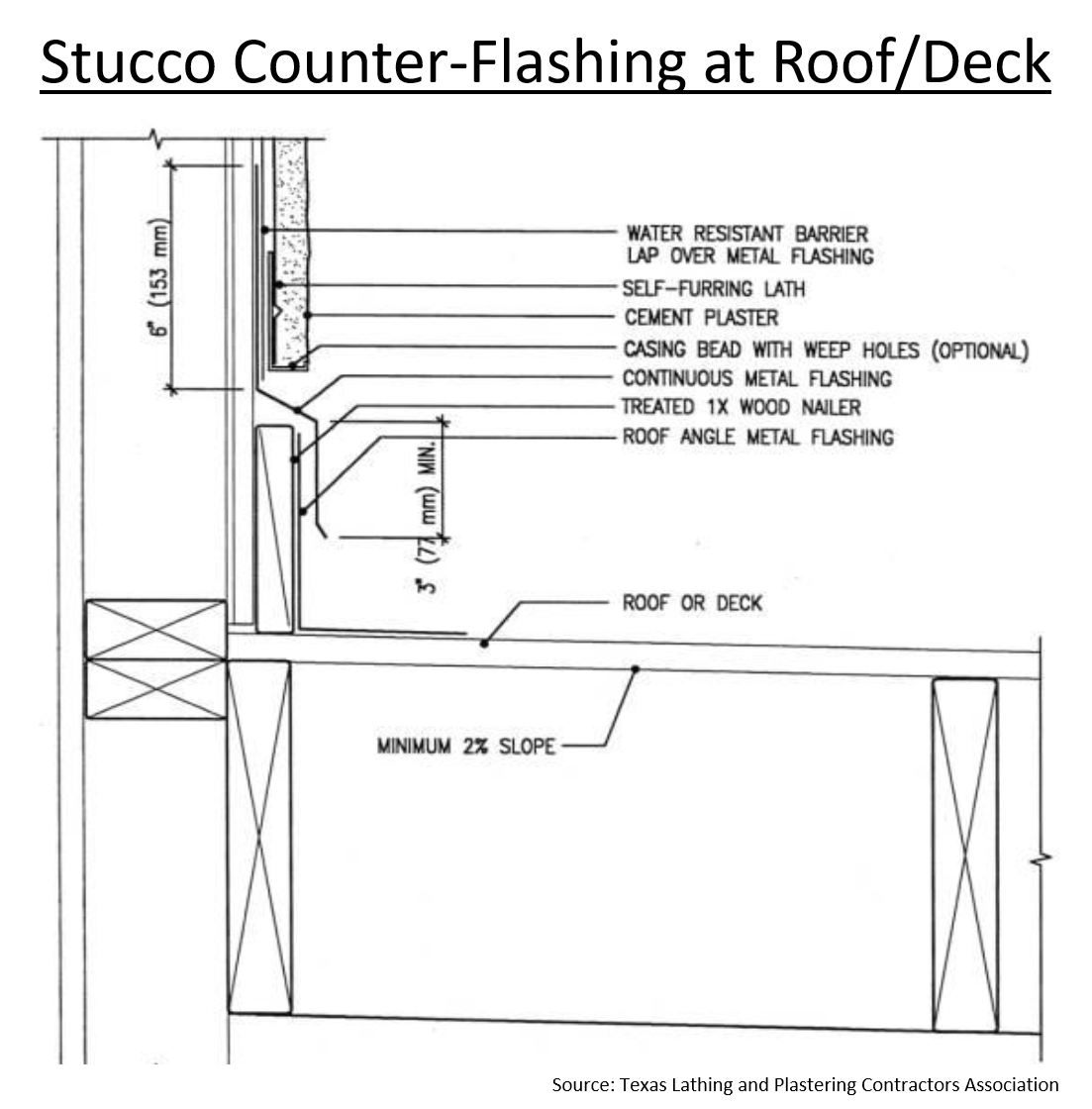

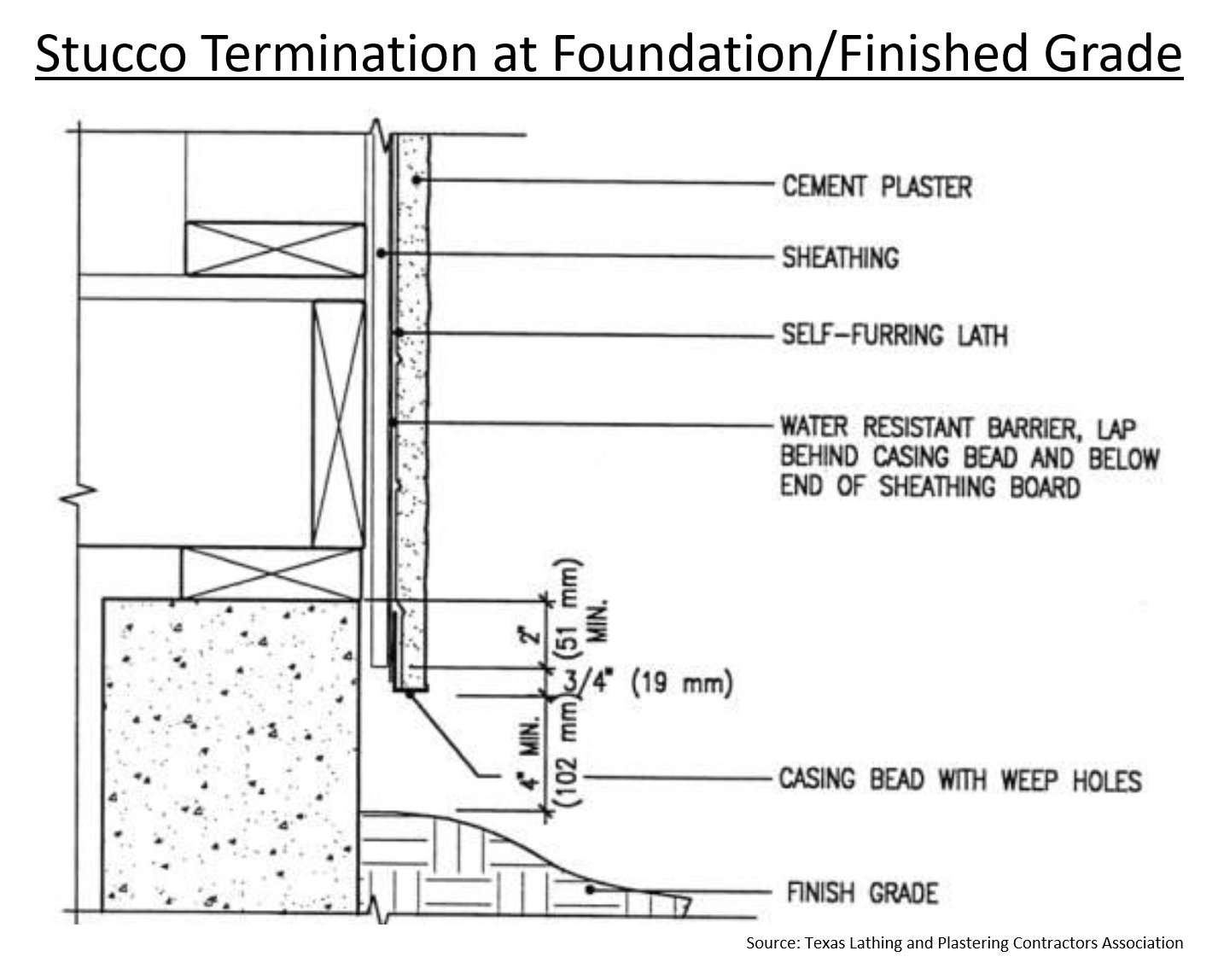

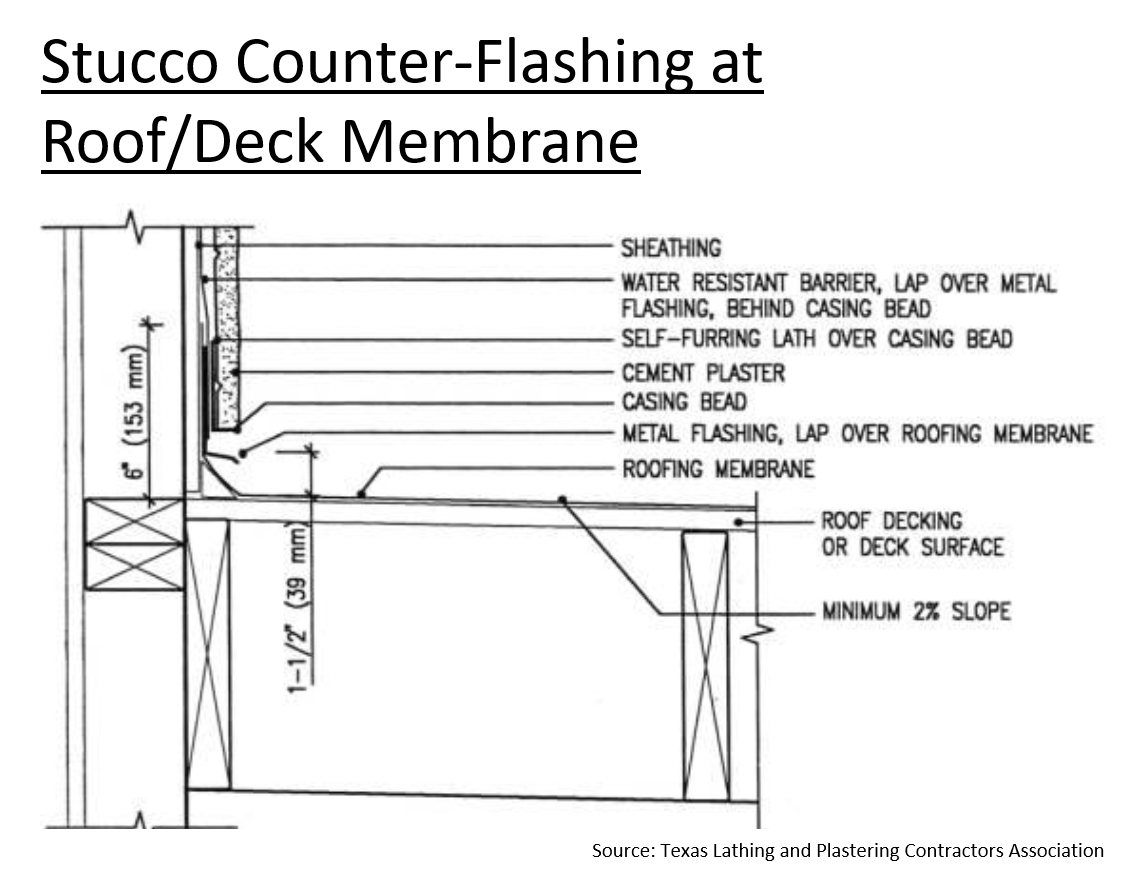

Detail: Wall to Roof/Deck Flashing (2020) Detail: Flashing a Nail-Flange Window (2018 rev) Detail: Control Joint at Floor Line (2016) Detail: Kick-Out Flashing for Stucco (2019) Detail: Sill Pan for Nail-Flange Windows (2020) Detail: Cantilevered Deck Joist - Stucco (2020) Detail: Stucco Parapets (2020) Detail: Corners for Stucco (2020)

Continuous Research for presentation Ting’s BTechIIIHealth Club

All Hardware. High Quality Builders' Necessities For Every Job. Quality Assured. UK's Leading PPE Supplier Renowned For Our Great Customer Service. Buy Well. Buy Safely.

Pin on Still Hollow House

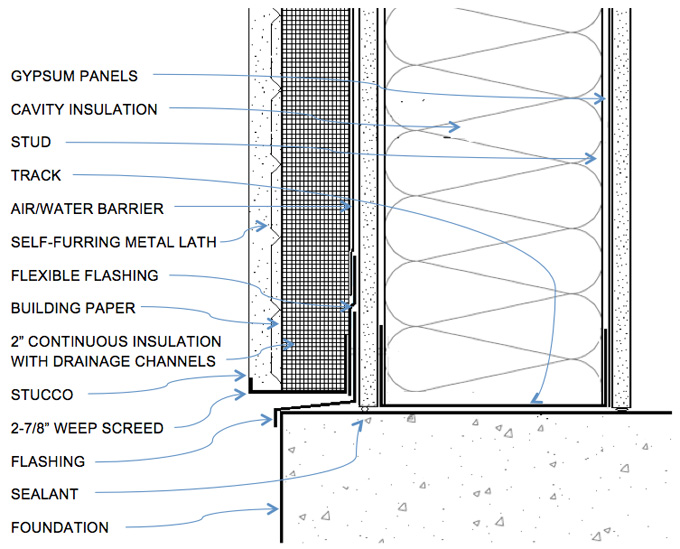

Attach the metal lath or welded wire lath with furring nails, which keep the metal spaced away from the waterproof building paper. Apply the three coats of stucco, and finish the bottom with a stop screed, or weep screed, about. 1/2 inch above the shingles. The step flashing should show enough to allow the application of a second layer of.